When its establishment, Hungaro-Ventilator Ltd. set the noble goal of developing and producing the ventilation equipment necessary for the supply of air to the people inside the buildings, be it fresh air supply or smoked air extraction systems.

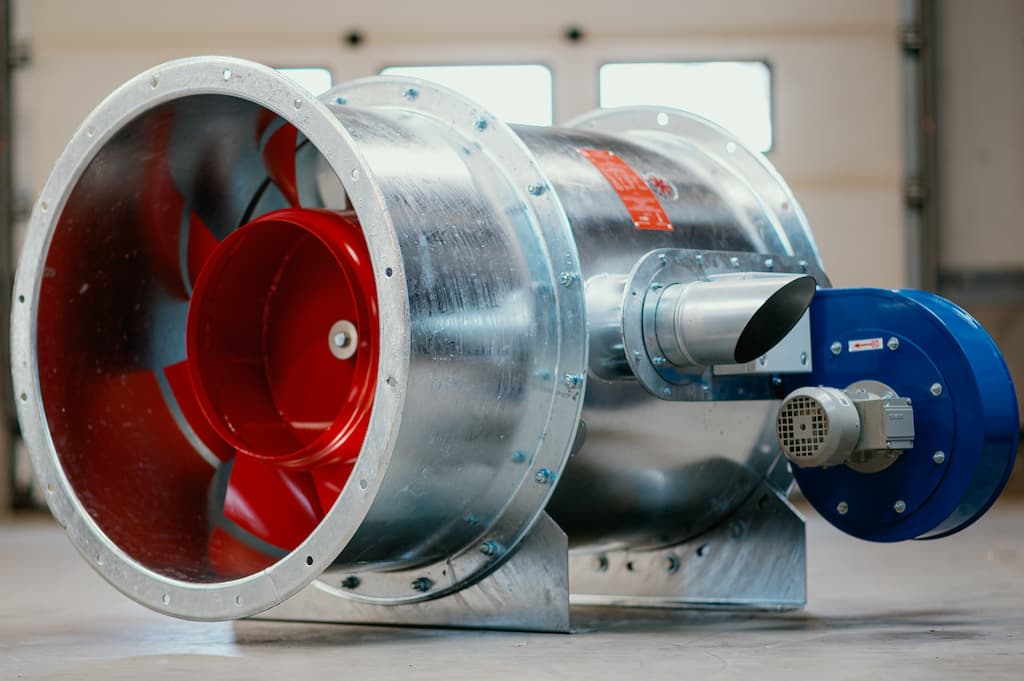

We pay special attention to the fresh air supply and high-temperature flue gas extraction fan equipment in the event of a building fire, which on the one hand ensures the survival of people trapped inside the building and on the other hand helps the work of firefighters.

Hungaro-Ventilator Ltd. manufactures smoke extraction and overpressure ventilation equipments and their accessories, the fire suitability of which is tested and certified and supervised by the MPA Braunschweig Institute in Germany.

Product Catalog

Download our current catalog!

Fields of Usage:

- Emergency smoke extraction fans in buildings. High temperature axial fans and axial roof fans fire class F200, F300, F400, F600 according to EN 12101-3. The accessories’s fire suitability are tested by together with the fan.

- Emergency ventilation fans in buildings. Axial fans and axial roof fans for supplying normal temperature fresh air. Fresh air is blown in place of the smoke extracted by the smoke extraction fans.

- Axial fans and axial roof fans for emergency supply of fresh air to pressurized stairwells in buildings, as well as automatic overpressure control dampers.

- Emergency high and normal temperature JET fans used in underground garages to divert smoke as well as exhaust gases.

- For emergency heat and smoke extraction of reversible large fans used in tunnels and subways. Largest size: ND 2500mm.

- Silencers used in building ventilation systems.

- Manual and motorized damper used for control or shut-off in building ventilation systems.

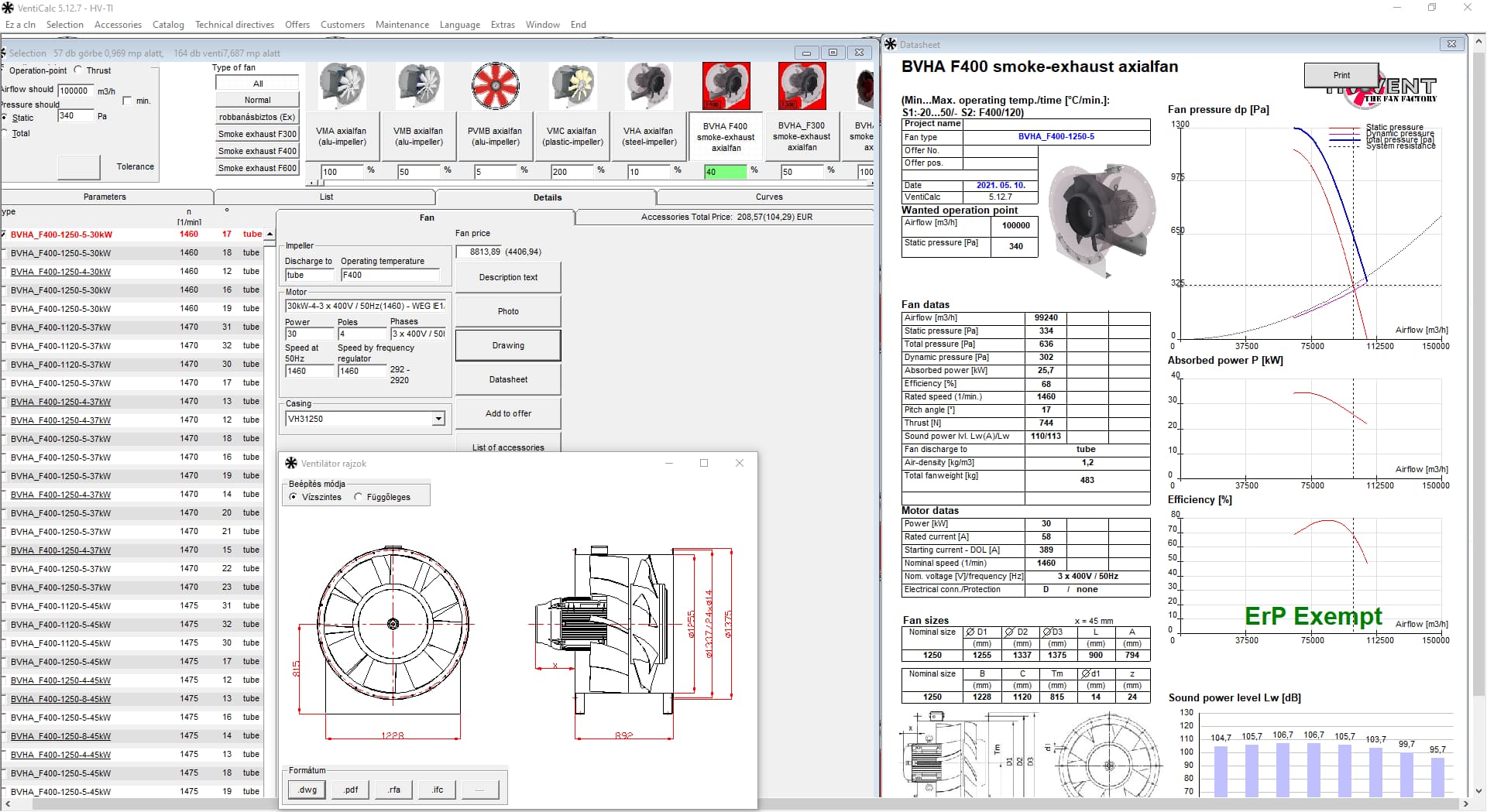

Configure your needs conveniently with the help of our VENTICALC selection program provided free of charge to our contracted partners!

The application is also available in English, German language from which the configurations can be sent directly to our Production Management System after finalization.